The Power of CAM Software in Modern Manufacturing

In the realm of modern manufacturing, Computer-Aided Manufacturing (CAM) software plays a crucial role in streamlining production processes, enhancing efficiency, and ensuring precision. CAM software is a digital solution that automates the manufacturing process by converting CAD (Computer-Aided Design) models into instructions for machines to create physical components.

One of the key advantages of CAM software is its ability to optimize machining operations and minimize human error. By generating toolpaths, simulating cutting processes, and identifying potential issues before production begins, CAM software helps manufacturers save time and reduce material waste.

Furthermore, CAM software enables manufacturers to achieve high levels of accuracy and consistency in their products. With advanced features such as multi-axis machining, adaptive toolpaths, and real-time monitoring, CAM software empowers manufacturers to create complex geometries with precision and efficiency.

Another benefit of CAM software is its scalability and flexibility. Whether it’s a small machine shop or a large-scale manufacturing facility, CAM software can be tailored to meet the specific needs and requirements of different industries. From aerospace components to medical devices, CAM software adapts to diverse manufacturing environments with ease.

As technology continues to evolve, the role of CAM software in modern manufacturing will only grow in importance. By harnessing the power of automation, optimization algorithms, and data analytics, CAM software enables manufacturers to stay competitive in a fast-paced global market.

In conclusion, CAM software is not just a tool but a strategic asset that drives innovation, efficiency, and quality in modern manufacturing. Embracing CAM software empowers manufacturers to unlock new possibilities, push boundaries, and redefine the future of production.

Top 5 FAQs About CAM Software: Understanding, Choosing, and Differentiating

- What is a CAM program?

- Is there any free CAM software?

- What software is needed for CAM?

- What is the difference between CAD and CAM software?

- Which CAM software is best?

What is a CAM program?

A CAM program, short for Computer-Aided Manufacturing program, is a digital tool used in the manufacturing industry to automate and optimize the production process. Essentially, a CAM program takes the design specifications from a CAD (Computer-Aided Design) model and translates them into precise instructions for machines to create physical components. By generating toolpaths, simulating machining operations, and ensuring accuracy and efficiency in production, CAM programs play a crucial role in modern manufacturing by streamlining processes, reducing errors, and enhancing overall productivity.

Is there any free CAM software?

When it comes to CAM software, a frequently asked question is whether there are any free options available. The answer is yes, there are several free CAM software solutions that cater to the needs of hobbyists, students, and small businesses. While some free CAM software may have limitations compared to their paid counterparts in terms of features and support, they still provide valuable tools for users to explore and learn about computer-aided manufacturing without a financial commitment. Popular free CAM software options include Fusion 360, FreeCAD, and CNC.js, offering users the opportunity to delve into the world of CAM without breaking the bank.

What software is needed for CAM?

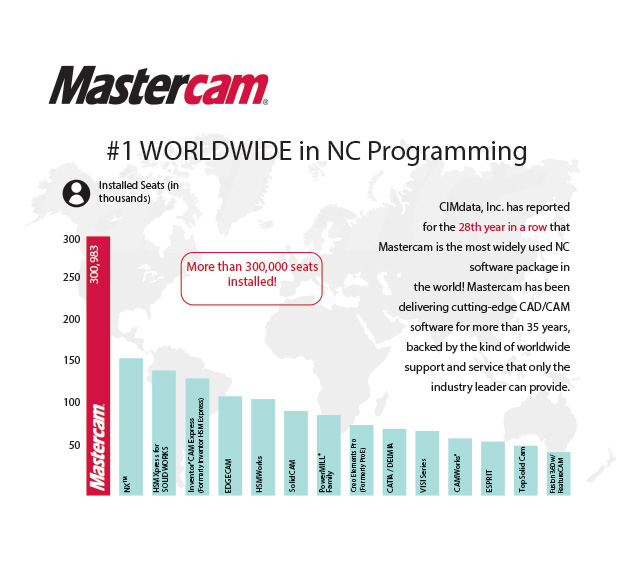

When it comes to Computer-Aided Manufacturing (CAM), the software needed typically includes specialized CAM software packages that are designed to work in conjunction with Computer-Aided Design (CAD) software. These CAM software solutions are specifically tailored to generate toolpaths, simulate machining processes, and convert CAD designs into instructions for CNC machines. Popular CAM software options include Autodesk Fusion 360, Mastercam, SolidCAM, and many others, each offering unique features and capabilities to meet the diverse needs of manufacturers across various industries. Choosing the right CAM software is essential for optimizing manufacturing processes, improving efficiency, and ensuring precision in production workflows.

What is the difference between CAD and CAM software?

CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software are two essential components in the modern manufacturing process. While CAD software is primarily used for creating detailed 2D or 3D designs of products, parts, or components, CAM software focuses on translating those designs into instructions for machines to produce physical objects. In essence, CAD software is the virtual design tool that allows engineers and designers to visualize and conceptualize their ideas, while CAM software takes those designs and generates toolpaths, calculates machining operations, and optimizes production processes for actual manufacturing. The key difference lies in their functionalities: CAD is about design creation, whereas CAM is about turning those designs into tangible products through automated manufacturing processes.

Which CAM software is best?

When it comes to choosing the best CAM software, the answer largely depends on individual needs, preferences, and specific requirements. There is no one-size-fits-all solution as different CAM software packages offer unique features, capabilities, and compatibility with various machines and manufacturing processes. It is essential to evaluate factors such as ease of use, technical support, cost-effectiveness, integration with existing systems, and the ability to meet specific production goals. Conducting thorough research, seeking recommendations from industry experts, and testing out trial versions can help in determining the most suitable CAM software for a particular application or business. Ultimately, the best CAM software is the one that aligns closely with the user’s workflow and enhances efficiency and productivity in manufacturing operations.

Tags: accuracy, automation, cad models, cam software, competitive advantage, computer-aided manufacturing, consistency, data analytics, efficiency, flexibility, machining operations, modern manufacturing, optimization algorithms, precision, scalability, toolpaths