The Importance of PLM Software in Modern Business

Product Lifecycle Management (PLM) software plays a crucial role in the success of modern businesses across various industries. PLM software helps companies manage the entire lifecycle of a product, from its conception to design, manufacturing, distribution, and even disposal.

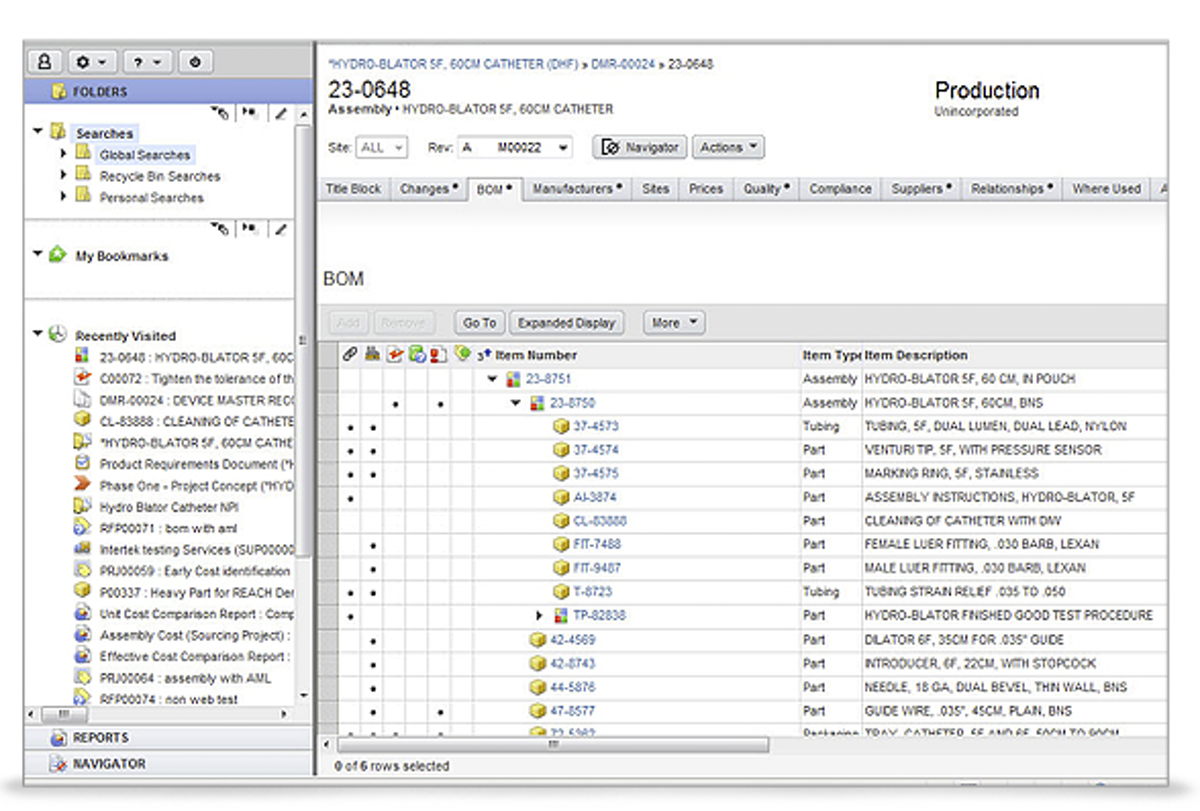

One of the key benefits of using PLM software is improved collaboration among different teams involved in product development. With PLM software, engineers, designers, manufacturers, and other stakeholders can work together seamlessly, sharing real-time data and updates to ensure that the product meets quality standards and deadlines.

PLM software also helps companies streamline their processes and reduce time-to-market for new products. By centralizing product data and automating workflows, businesses can eliminate inefficiencies and bottlenecks that often occur during product development.

Another advantage of PLM software is enhanced visibility and traceability throughout the product lifecycle. Companies can track changes made to the product design, monitor supplier relationships, and ensure compliance with regulatory requirements more effectively with PLM software.

In addition, PLM software enables companies to make informed decisions based on accurate data and analytics. By analyzing performance metrics and customer feedback collected through PLM software, businesses can identify areas for improvement and innovation to stay ahead of the competition.

In conclusion, investing in PLM software is essential for modern businesses looking to optimize their product development processes, enhance collaboration among teams, accelerate time-to-market, ensure regulatory compliance, and drive innovation. With the right PLM solution in place, companies can achieve greater efficiency, productivity, and success in today’s competitive market.

Top 5 Benefits of PLM Software: Boosting Collaboration, Efficiency, and Compliance

- Enhanced collaboration among teams involved in product development.

- Streamlined processes leading to reduced time-to-market for new products.

- Improved visibility and traceability throughout the product lifecycle.

- Informed decision-making through data analytics and performance metrics.

- Facilitates compliance with regulatory requirements and quality standards.

7 Key Challenges of Implementing PLM Software: Costs, Integration, and Adoption Hurdles

- High initial investment and implementation costs

- Steep learning curve for users unfamiliar with PLM software

- Integration challenges with existing systems and workflows

- Potential for data security risks if not properly configured or maintained

- Dependency on vendor support for updates, maintenance, and troubleshooting

- Customization limitations that may not fully meet unique business requirements

- Possible resistance from employees to adopt new processes and tools

Enhanced collaboration among teams involved in product development.

Enhanced collaboration among teams involved in product development is a significant benefit of utilizing PLM software. By providing a centralized platform for sharing real-time data, updates, and feedback, PLM software fosters seamless communication and coordination among engineers, designers, manufacturers, and other stakeholders. This improved collaboration ensures that all team members are on the same page, working towards common goals, and contributing their expertise effectively throughout the product lifecycle. As a result, companies can streamline their processes, reduce errors and delays, and ultimately deliver high-quality products to market more efficiently.

Streamlined processes leading to reduced time-to-market for new products.

One of the significant advantages of implementing Product Lifecycle Management (PLM) software is the ability to streamline processes, ultimately resulting in reduced time-to-market for new products. By centralizing product data, automating workflows, and facilitating collaboration among different teams, PLM software eliminates inefficiencies and bottlenecks that can delay product development. This streamlined approach not only accelerates the product development cycle but also enables companies to bring innovative products to market faster, gaining a competitive edge in today’s fast-paced business environment.

Improved visibility and traceability throughout the product lifecycle.

One significant advantage of Product Lifecycle Management (PLM) software is the enhanced visibility and traceability it provides throughout the product lifecycle. By utilizing PLM software, companies can effectively track changes made to product designs, monitor supplier relationships, and ensure compliance with regulatory requirements. This improved visibility and traceability enable businesses to make informed decisions based on accurate data and analytics, ultimately leading to better product quality, streamlined processes, and increased efficiency in managing the entire lifecycle of a product.

Informed decision-making through data analytics and performance metrics.

One significant advantage of utilizing PLM software is the ability to make informed decisions through data analytics and performance metrics. By leveraging the data collected and analyzed within the PLM system, businesses can gain valuable insights into various aspects of product development, such as design efficiency, production costs, supplier performance, and customer feedback. This data-driven approach empowers companies to identify trends, patterns, and opportunities for improvement, enabling them to make strategic decisions that drive innovation, optimize processes, and ultimately enhance overall business performance.

Facilitates compliance with regulatory requirements and quality standards.

One significant advantage of using Product Lifecycle Management (PLM) software is its ability to facilitate compliance with regulatory requirements and quality standards. By centralizing product data and documentation, PLM software helps companies ensure that their products meet all necessary regulations and industry standards. This streamlined approach not only saves time and effort in managing compliance but also reduces the risk of errors or oversights, ultimately enhancing the overall quality and reliability of the products being developed.

High initial investment and implementation costs

One significant drawback of PLM software is the high initial investment and implementation costs associated with adopting such a system. For many businesses, especially small and medium-sized enterprises, the upfront expenses of purchasing and setting up PLM software can be prohibitive. Additionally, the implementation process often requires extensive training for employees, customization to fit specific business needs, and ongoing maintenance costs. This financial barrier can deter some companies from fully leveraging the benefits of PLM software, limiting their ability to streamline product development processes and stay competitive in the market.

Steep learning curve for users unfamiliar with PLM software

One significant drawback of PLM software is the steep learning curve it presents for users who are unfamiliar with the system. Due to its complexity and extensive features, mastering PLM software can be challenging and time-consuming for new users. This hurdle may lead to frustration, decreased productivity, and resistance to adoption within an organization. Training and support are crucial to help users overcome this obstacle and fully leverage the benefits of PLM software in streamlining product development processes.

Integration challenges with existing systems and workflows

One significant drawback of PLM software is the integration challenges it poses with existing systems and workflows within an organization. Implementing PLM software often requires seamless integration with other enterprise systems, such as ERP (Enterprise Resource Planning) or CRM (Customer Relationship Management) systems, which can be complex and time-consuming. Discrepancies in data formats, compatibility issues, and resistance from employees accustomed to legacy workflows can hinder the smooth adoption of PLM software, leading to disruptions in operations and potential inefficiencies. Organizations must carefully plan and strategize the integration process to mitigate these challenges and ensure a successful transition to a unified product lifecycle management system.

Potential for data security risks if not properly configured or maintained

One significant con of PLM software is the potential for data security risks if not properly configured or maintained. Inadequate security measures or lax maintenance of PLM systems can leave sensitive product data vulnerable to cyber threats, unauthorized access, or data breaches. Without robust security protocols in place, companies using PLM software may face serious consequences, including loss of intellectual property, compromised confidential information, and damage to their reputation. It is crucial for businesses to prioritize data security and regularly update and monitor their PLM systems to mitigate the risk of security breaches and protect valuable assets.

Dependency on vendor support for updates, maintenance, and troubleshooting

One significant drawback of using PLM software is the dependency on vendor support for updates, maintenance, and troubleshooting. Companies relying on PLM software may face challenges when they encounter issues or require software updates, as they are often reliant on the vendor to provide timely assistance. This dependency can lead to potential delays in resolving technical issues, implementing necessary updates, or addressing maintenance concerns, ultimately impacting the efficiency and effectiveness of the organization’s product development processes.

Customization limitations that may not fully meet unique business requirements

One significant drawback of PLM software is the customization limitations that may hinder its ability to fully meet unique business requirements. While many PLM solutions offer a range of features and functionalities, they may not always align perfectly with the specific needs of every organization. This can result in businesses having to compromise or work around certain limitations, leading to inefficiencies and potential gaps in their product development processes. Customization constraints in PLM software can restrict innovation and flexibility, making it challenging for companies to tailor the software to their individual workflows and preferences effectively.

Possible resistance from employees to adopt new processes and tools

One potential drawback of implementing PLM software in a business is the resistance that may arise from employees when adapting to new processes and tools. Change can be challenging for some individuals, especially if they are accustomed to existing workflows and systems. Employees may feel overwhelmed by the learning curve associated with the new PLM software, leading to reluctance in embracing the technology fully. It is crucial for organizations to provide adequate training, support, and clear communication to address employee concerns and facilitate a smooth transition to the new PLM system. By proactively addressing resistance and promoting a culture of openness to change, businesses can help employees overcome their apprehensions and leverage the benefits of PLM software effectively.

Tags: collaboration, data analytics, efficiency, importance, innovation, modern business, plm software, product development, product lifecycle management, regulatory compliance, streamline processes, teams, time-to-market, traceability, visibility